MACHINING

MACHINING

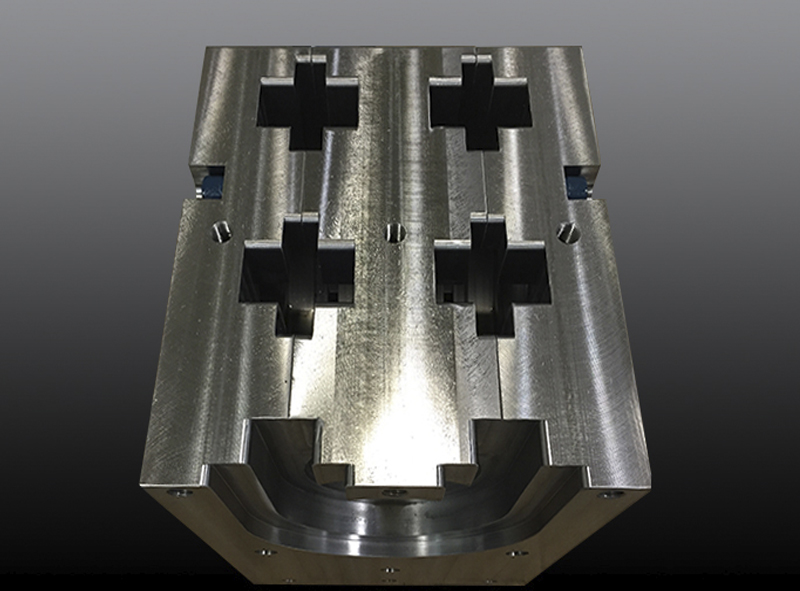

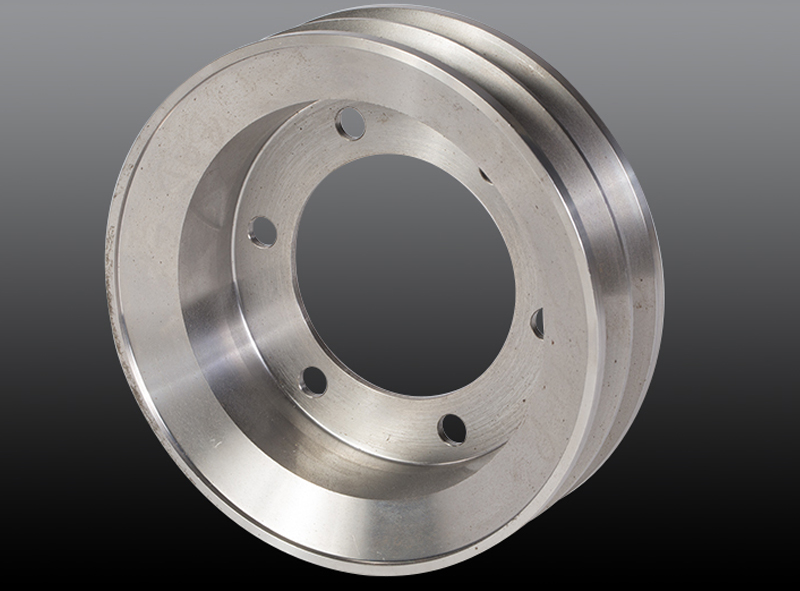

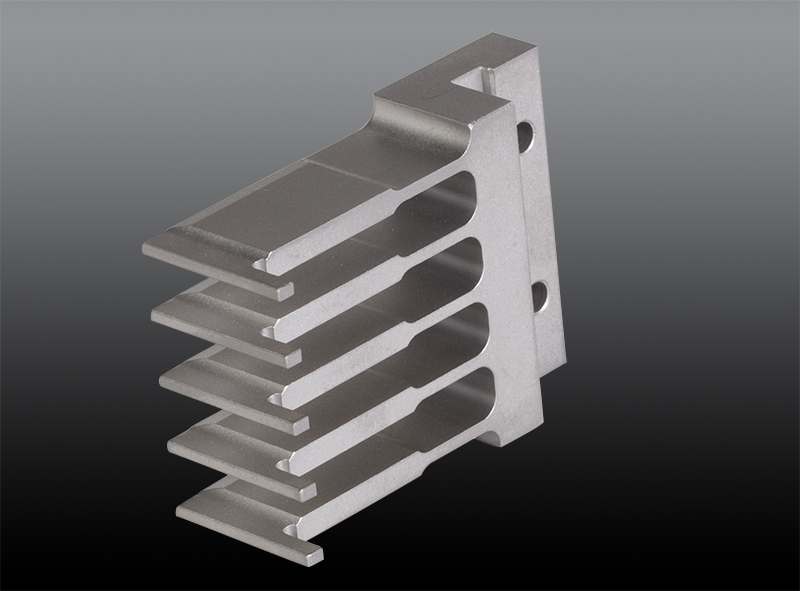

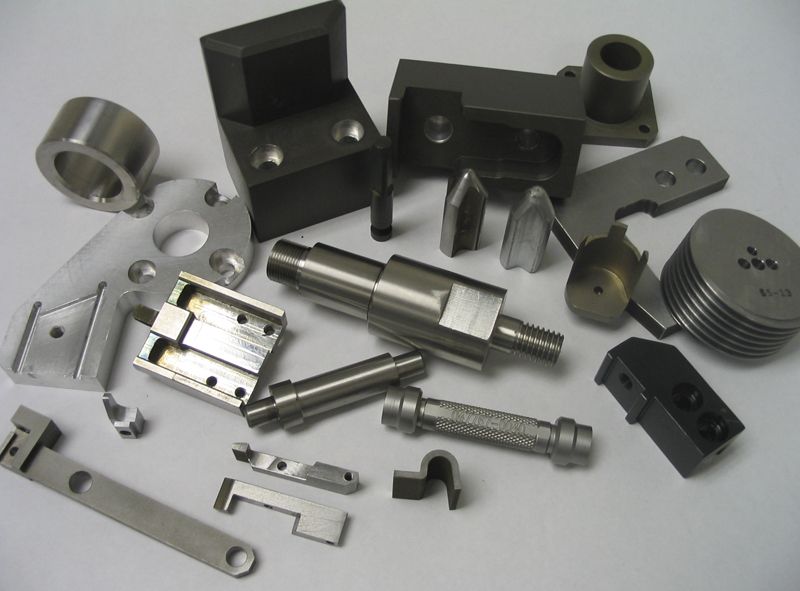

At Jorgensen we believe that the value we bring to our customer base stems from many aspects of our business. For example, we have machining and fabrication capabilities for small and large components and assemblies. In addition, we are capable of handling low quantity (prototype) and high quantity (production) projects. In other words, our value proposition is our extensive breath of capabilities. This allows us to focus on being extremely competitive while enhancing the quality of our products and services.

Jorgensen offers you longstanding experience in technical and complex manufacturing solutions, including precision CNC machining and precision CNC turning services. As a leader in using state of the art practices and systems, Jorgensen supports our customers in today’s changing markets. Contact Jorgensen to learn more about all of our CNC machining services, including CNC milling, large CNC machining, and precision CNC turning.

Prototype

Jorgensen can work closely with your engineers and design teams to help you develop the product you desire.

Production

Jorgensen has maintained production runs ranging from low to very high volume parts. Many companies have come to recognize Jorgensen as a high quality production facility.

Materials

Jorgensen has the experience and capabilities to machine various types of material: carbon steel, stainless steel, aluminum, cast iron, aluminum bronze, Nitronic 60, Ni-resist, 17-4, Stellite, as well as many other materials, including exotic metals. Our machinist employees have over 100 years combined experience to complete your next complex project.

Equipment and Capabilities

Machine Center Milling

- Okuma Horizontal Space Center MA-500H II X:700 Y:900 Z:780

- Mazak Vertical Machining Center Nexus 510C II 510 x 1300 x 570 capacity

- Trak FHM7, 20” x 36” x 60” Capacity, Prototrak SMX CNC

- (2)Trak DPM5, 20” x 15” x 40” Capacity, Prototrak SM CNC Controls

- Trak DPM, 20” x 15” x 32” Capacity, Prototrak SMX CNC Controls

- Bridgeport Mill – 20” x 15” x 30” Capacity, Acu-rite CNC Controls

- Devlieg Boring Mill, 60” x 48” Capacity, Model 4-B

- OKK- VM5 II, Mitsubishi Neomatic 635 CNC Control, 20″ x 40” Capacity

Machine Center Turning

- Okuma Genos L400E Lathe, Dia. 12” x 40”

- Okuma LB3000EX, Live tooling with milling, Dia. 13.25” x 40”

- Clausing Manual Lathe, Dia. 10” x 36”

- Clausing Colchester Manual Lathe, Dia. 17″ x 96″

Machine Center Grinding

- Parker Majestic Surface Grinder, 6” x 18”

- Chevalier Surface Grinder – FSG-3A1224H, 12” x 24”

Machine Center EDM

- Mitsubishi Wire EDM Machine, FA10S, 7-3/4” x 9-1/2” x 13-1/2”